i-Chem Solution- Multi-Disc Screw Press Sludge Dewatering System

Category: Multi-Disc Screw Press

Specifications

Details

Source the right Multi Disc Screw Press for Your Waste Water Treatment Plant ! We are the pioneer in the industry.

Multi-Disc Screw Press

Multi-Disc Screw Press

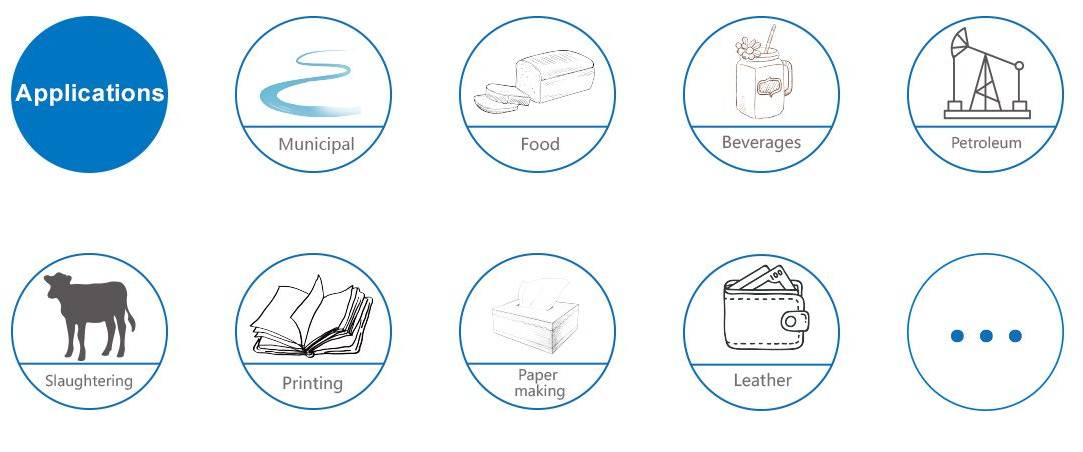

- Multi-Disk Screw Press (MDS) is an advance sludge dewatering equipment that follows the dewatering principles of force-water current and thin layer dewatering. The pitch of the screw and the gaps between the rings decrease towards the direction of sludge cake outlet, increasing its internal pressure due to the volume compression effect, filtrate is drained out from the sludge, producing an exceptionally dry sludge cake. Due to the innovation of structure design, it is highly suitable for various high and low concentration sludge (2000mg/L-50000mg/L), most especially the oily sludge. Machine’s self-cleaning feature and clog free design makes MDS delivers massive saving in operation cost, widely used in municipal sludge food, beverage, slaughtering breeding, printing and dyeing, oil chemical industry, paper making, leather, pharmaceutical and other industries of sludge dewatering process.

- The purpose of screw press is to save water, energy and carbon footpprint.

.jpeg)

Model References :

-

Model Raw Wastewater/Chemically Precipitated Sludge/Waste Activated Sludge Dissolved Air Flotation Mixed Raw Sludge/Aerobic Digested Sludge/ Sewage Sludge Sludge Concentration (TS) 0.2% 1 % 2% 5% 3% MDS-101 ~2kg-DS/h

(~1.0m3/h)~3kg-DS/h

(~0.3m3/h)~5kg-DS/h

(~0.25m3/h)~10kg-DS/h

(~0.2m3/h)~13kg-DS/h

(~0.43m3/h)MDS-131 ~4kg-DS/h

(~2.0m3/h)~6kg-DS/h

(~0.6m3/h)~10kg-DS/h

(~0.5m3/h)~20kg-DS/h

(~0.4m3/h)~26kg-DS/h

(~0.87m3/h)MDS-132 ~8kg-DS/h

(~4.0m3/h)~12kg-DS/h

(~1.2m3/h)~20kg-DS/h

(~1.0m3/h)~40kg-DS/h

(~0.8m3/h)~52kg-DS/h

(~1.73m3/h)MDS-202 ~16kg-DS/h

(~8.0m3/h)~24kg-DS/h

(~2.4m3/h)~40kg-DS/h

(~2.0m3/h)~80kg-DS/h

(~1.6m3/h)~104kg-DS/h

(~3.47m3/h)MDS-301 ~20kg-DS/h

(~10.0m3/h)~30kg-DS/h

(~3.0m3/h)~50kg-DS/h

(~2.5m3/h)~100kg-DS/h

(~2.0m3/h)~130kg-DS/h

(~4.33m3/h)MDS-302 ~40kg-DS/h

(~20.0m3/h)~60kg-DS/h

(~6.0m3/h)~100kg-DS/h

(~5.0m3/h)~200kg-DS/h

(~4.0m3/h)~260kg-DS/h

(~8.67m3/h)MDS-352 ~80kg-DS/h

(~40.0m3/h)~120kg-DS/h

(~12.0m3/h)~200kg-DS/h

(~10.0m3/h)~400kg-DS/h

(~8.0m3/h)~520kg-DS/h

(~17.3m3/h)MDS-353 ~120kg-DS/h

(~60.0m3/h)~180kg-DS/h

(~18.0m3/h)~300kg-DS/h

(~15.0m3/h)~600kg-DS/h

(~12.0m3/h)~780kg-DS/h

(~26.0m3/h)MDS-354 ~160kg-DS/h

(~80.0m3/h)~240kg-DS/h

(~24.0m3/h)~400kg-DS/h

(~20.0m3/h)~800kg-DS/h

(~16.0m3/h)~1040kg-DS/h

(~35.0m3/h)MDS-403 ~200kg-DS/h

(~100.0m3/h)~300kg-DS/h

(~30.0m3/h)~510kg-DS/h

(~25.5m3/h)~1020kg-DS/h

(~20.4m3/h)~1326kg-DS/h

(~44.2m3/h)

This machine is widely applied in Food and Beverage Industry and Palm Oil Mill.

Welcome to reach out our engineers for supports in MDS sludge dewatering system.

Welcome to reach out our engineers for supports in MDS sludge dewatering system.

View more about i-Chem Solution- Multi-Disc Screw Press Sludge Dewatering System on main site